PU/Phenolic insulation panel uses closed-cell rigid foam as its core material finely formuated by mixing phenolic resin, anti-combusion agent, smoke suppressant, hardening agent, foaming agent and other additives. The laminated panel is between 20 an..

PU/Phenolic insulation panel uses closed-cell rigid foam as its core material finely formuated by mixing phenolic resin, anti-combusion agent, smoke suppressant, hardening agent, foaming agent and other additives. The laminated panel is between 20 and 30 mm in thickness, 1200mm in width, length determined by the customer. The same production line can be used to make insulating panels with different flexible facing layers. The operation principle of this line is as follows: Raw materials of rigid-foam liquids are delivered into the mixing head in a given ratio through the metering pump on the injection machine and then injected onto panel's bottom facing sheet going toward conveyors along with the top superficial sheet. PU/Phenolic foam material with high performance is suitable for more demanding envoironment such as these arthitectures requiring good anti-combustion and thermal insulation e.g. pre-fabricated industrial or civil building, coldroom, clean room, temporary building, gym and supermarket, etc.. PU/Phenolic material has broad and bright prospects for its further development. With its outstanding advantages of fire resistance and thermal insulation, Phenolic panel has good properties of corrosion and aging resistance, small density and light weight and sound absoprtion and environmental protection.

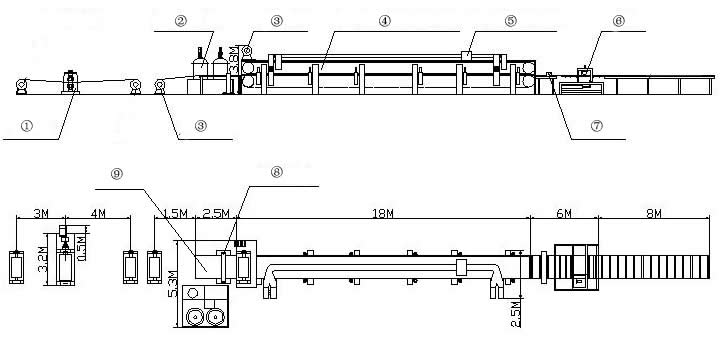

Main constituents

1. Embossing machine unit 2. Reaction injection machine 3. Foil decoiler 4. Double-belt laminator

5. Hot-air circulator 6. Cross-cutter 7. Edge-trimming installation 8. Mobile injector 9. Pre-heating table

1. Embossing machine unit: For embossing foil from 0.06 to 0.12mm thick. Max.loading coil: 2000kg.

2. Reaction Injection machine: To meter and mix two different liquid components in a given mixing ratio required by technical process. A chiller and a temperature controller are equipped to meet the temperature requirements of foaming liquid chemicals. We have both high and low pressure machines for user's optional use.

3. Foil decoiler: Double-coil or single coil loader for client's choice with loading coil weight up to 1000kg.

4. Double-belt laminator: Options of laminator's length: 12m, 18m, 24m, 30m or 36m; speed range: 3 to 8m/min. Materials of laminator's conveyor plank can be either steel or aluminum as per client's choice.

5. Hot-air circulator: Used to heat up laminator's belt conveyors in an optimal design of air circulation route which can heat to 60℃ from 20℃ in one hour. There are both furnace and electricty heaters equipped on the line while the funace can either use fuel oil or steam as heating energy depending on customer's choice.

6. Cross-cutter: With single or double pull broaches or disc-saw auto-tracking cutters for optional use. (Pls refer to the introduction on cutter series under matching equipment ).

7. Edge-trimming installation: There are both knife and disc-saw trimming installations for customer's coice.

8. Mobile injector: The user can choose either a hydralic motor or servo motor with a crank as the driving system.

9. Pre-heating table: To heat to 40℃, temperature adjustable.

Main technical parameters

Specification of produced panel 1200 mm×20~30 mm (Width×Thickness), Length on request

Linear speed of production 2~5 m/min

Maximum embossing speed 15 m/min max.

Agitating speed 4500 r/min

Reciprocating times of injection head per minute more than 60

Maximum temperature of hot-air circulating 70℃

Laminating length of laminator 18 m

Maximum clearance between conveyors 250 mm

Total power (KVA) 85~125

Overall external dimensions 40340×5365×3636 mm (Length×Width×Height)

Eexternal dimensions of embossing machine unit 7050×3200×1600 mm (Length×Width×Height)

Weight ≈33 tons

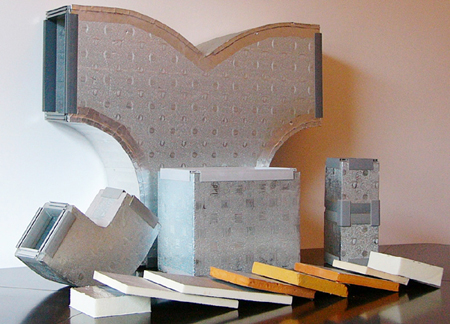

Picture of finished product